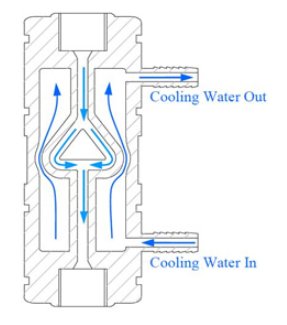

The microfluidization high-pressure homogenizer is a high-pressure homogenizer equipped with the second-generation microfluidic diamond interactive chamber. It utilizes dynamic high-pressure microfluidization, high shear, high-energy collision (turbulent collision), cavitation and other forces during the nano-processing of materials. It is suitable for liquid-liquid emulsification, lipid preparation, nano-dispersion of solid materials in liquids, deagglomeration, particle size reduction, and cell disruption, etc. These core high-energy reactions of the microfluidic high-pressure homogenizer all happened in a microfluidic diamond interaction chamber with an internal fixed shape (Z-shape or Y-shape) and a specific aperture.

Microfluidic diamond interactive chamber :

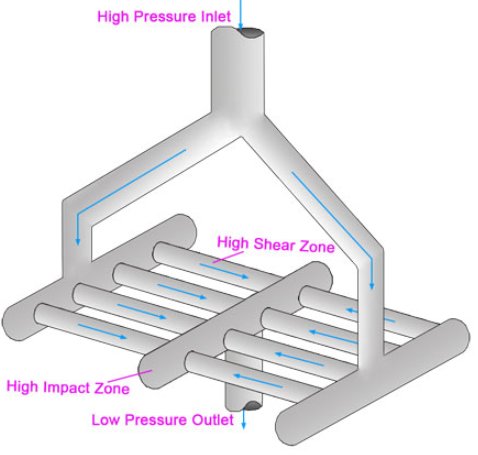

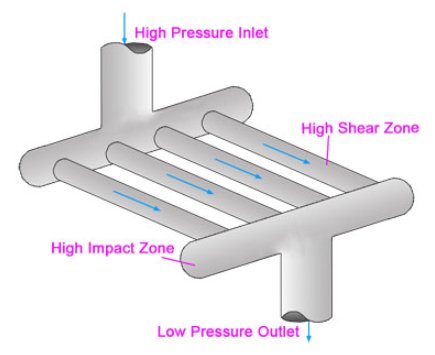

The microfluidic diamond interactive chamber is the place where high-speed jet, high shear, high-energy collision and other effects occur. It’s interior has fixed Y or Z-shaped diamond micro-channels, and the minimum diameter can reach 50um. The fixed geometry guarantees consistent effect (precise and fully reproducible particle size distribution) is achieved.

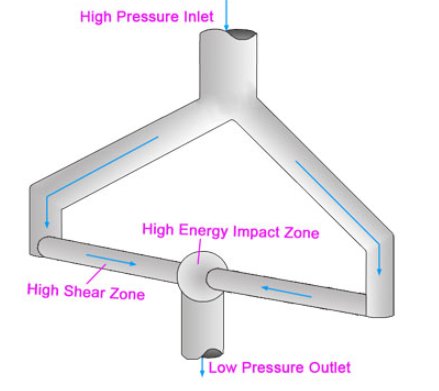

Single channel Y-shape diamond interaction chamber

Single channel Y-shape diamond interaction chamber

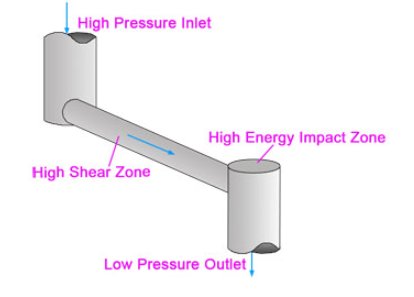

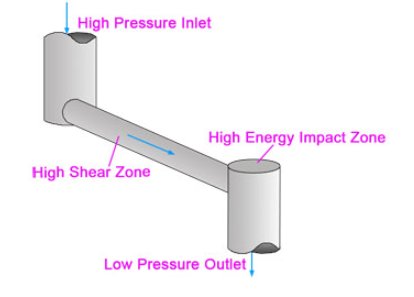

Single channel Z-shape diamond interaction chamber

Single channel Z-shape diamond interaction chamber

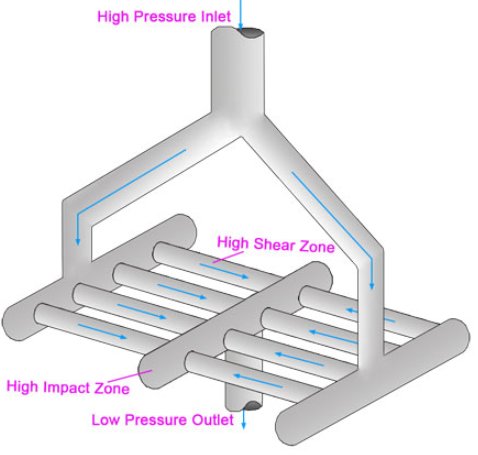

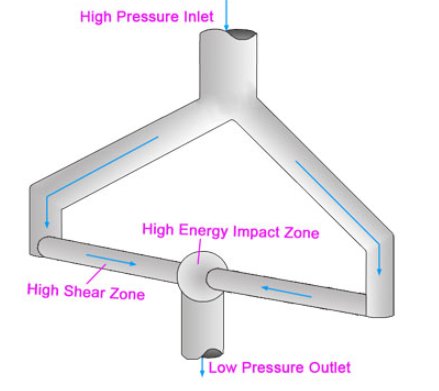

Multi-channel Y-shape diamond interaction chamber

Multi-channel Y-shape diamond interaction chamber

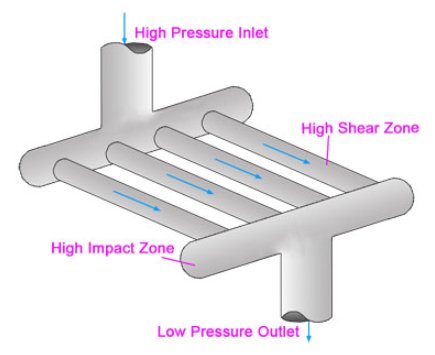

Multi-channel Z-shape diamond interaction chamber

Multi-channel Z-shape diamond interaction chamber

Feature 1. Extremely high shear force

Feature 2. Fixed internal structure and consistent reaction pressure

Feature 3. Counter Jet

Feature 4. Good reproducibility

Feature 5. Guaranteed scale-up production

Single channel Y-shape diamond interaction chamber

Single channel Y-shape diamond interaction chamber Single channel Z-shape diamond interaction chamber

Single channel Z-shape diamond interaction chamber Multi-channel Y-shape diamond interaction chamber

Multi-channel Y-shape diamond interaction chamber Multi-channel Z-shape diamond interaction chamber

Multi-channel Z-shape diamond interaction chamber