Application

● Injection preparation

● Biological technology

● Liposome cosmetics

● Fine chemical industry

● New energy materials

● Food and beverage

Standard Configuration

● The core component of homogenizer adopts diamond interaction chamber, Y type and Z type can be configured, and the particle size can be homogenized below 100nm.

● The contact materials include SUS 316L stainless steel, SUS 630 stainless steel, UHMWPE, PEEK, PTFE.

● Support high-pressure plunger seal cooling design to extend service life.

● Equipped with material heat exchanger, it can cooperate with cooling water to effectively control the discharge temperature, and protect product activity.

● Standard with 1L stainless steel hopper.

● Equipped with emergency stop button.

● Equipped with roller wheels at the bottom for easy movement.

Working Principle

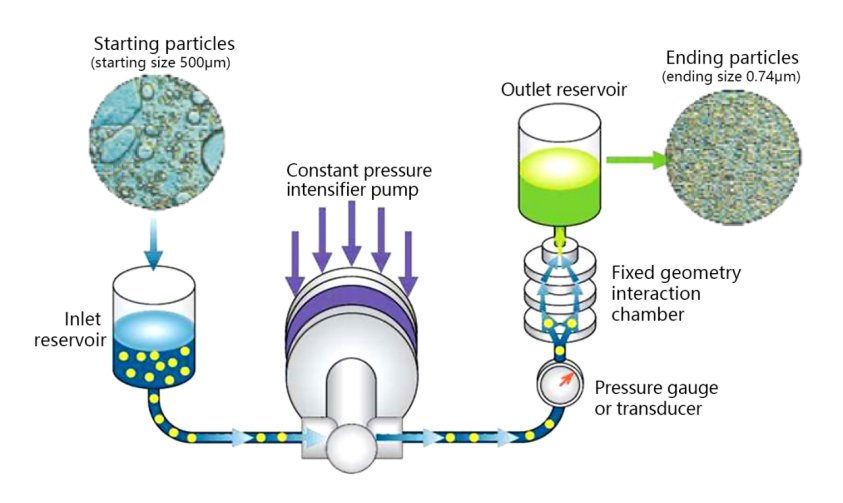

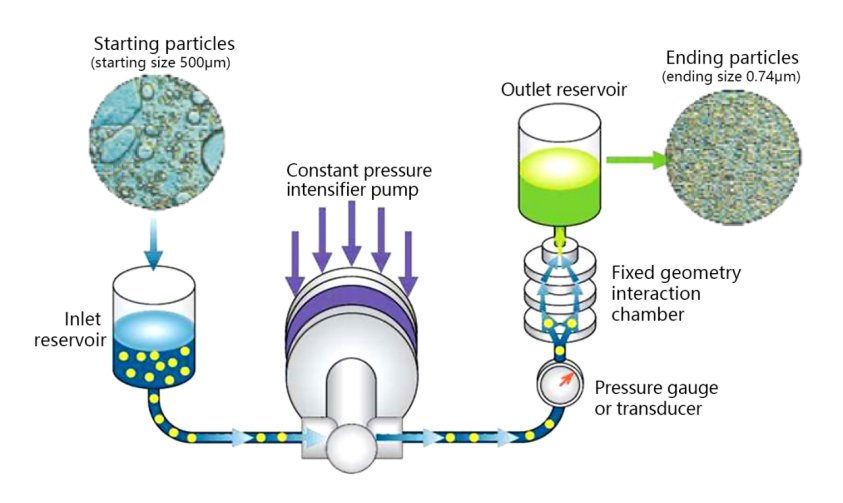

Electrichydraulic module powers a single acting intensifier pump. Process pressures can be selected by simply turning the knob. As the pump travels through its pressure stroke, it drives the product at constant pressure through the processor. A specially designed fixedgeometry microchannels inside the processor accelerates the product stream to high velocities, creating high shear and impact forces that bring about the desired results. As the intensifier pump completes its pressure stroke, it reverses direction and draws in a new volume of product. At the end of the intake stroke, it reverses direction and again drives the product at constant pressure, repeating the process. Upon exiting the processor, the product flows through heat exchanger which regulates the product to a desired temperature. The product may be recirculated through the system for further processing or directed externally to the next step in the process.

Optional Configuration

● 2L or 4L stainless steel hopper

● Diaphragm pressure sensor with digital display

● Temperature detection and digital display of outlet port

● Explosion-proof design

● Cooling jacket for diamond interaction chamber

● CIP, SIP

● Low design pressure and high flow rate plunger system